Types of silicone valves

- Silicone One Way Valve

- Silicone Cross Slit Valve

- Silicone Valve Seal

- Bottle Cap Check Valve

- Ketchup Bottle Silicone Valve,etc…

Common Sizes

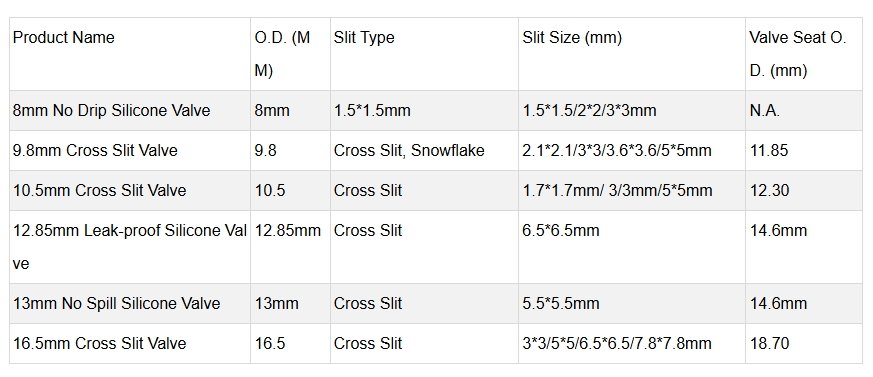

Silicone valves come in various sizes and can be customized based on specific application needs. Common sizes include:

Diameter Range: 2mm – 50mm

Thickness: 0.3mm – 5mm

Opening Types: Cross slit, V-shaped slit, circular opening, etc.

We have T-10,T-13,T-16 size in stock.

Applications

1. Food and Beverage Industry

Bottle cap check valves

Ketchup bottle silicone valves

2. Medical and Pharmaceutical

Fluid control in medical devices such as respiratory equipment and injection systems.

Sealing valves in reagent bottles and pharmaceutical containers

3. Personal Care and Cosmetics

Dispensers for skincare and hygiene products

Anti-backflow silicone valves in cosmetic packaging.

4. Industrial and Automotive

One-way valves in gas and liquid pipelines.

Fluid control components in automotive fuel or cooling systems.

5. Laboratory and Scientific Equipment

Fluid control valves in precision instruments

Sealing and dispensing solutions for chemical reagent bottles.

Silicone Valves Manufacturing: Methods and Process Overview

Silicone valves are essential components in many fluid dispensing systems, offering precision control and leak-proof functionality. Their manufacturing involves two main methods: compression molding and liquid silicone rubber (LSR) injection molding. The chosen method depends largely on the valve’s structure and the volume required.

Compression Molding vs. LSR Injection Molding

Compression molding is ideal for smaller batches or simple designs. It involves placing preformed silicone into a heated mold cavity, then applying pressure to shape it.

LSR injection molding, on the other hand, is best suited for high-volume production and complex geometries. It ensures consistent quality with tight tolerances, ideal for valves requiring precision performance.

The Importance of Mold Design and Fabrication

At the heart of silicone valve manufacturing lies mold design and mold making. A well-engineered mold ensures accurate replication of the valve’s specifications—be it the size, slit design, or flow control function.

This step begins with close collaboration between product engineers and mold designers. Advanced CAD software is used to simulate the valve’s behavior under real-world conditions. Once finalized, high-precision tooling is produced using CNC machining or EDM (electrical discharge machining), ensuring the mold meets strict industry standards.

A high-quality mold is critical—it not only defines the valve’s performance but also determines the efficiency and longevity of the production process.

Quality Inspection: Ensuring Precision and Performance

The final and most critical step in silicone valve manufacturing is quality inspection. At this stage, each valve undergoes thorough evaluation to ensure it meets stringent industry standards and customer-specific requirements.

Inspectors check for:

Visual defects like surface blemishes, warping, or flashing.

Dimensional accuracy using precision measuring tools to verify that critical features—such as the slit thickness, outer diameter, and seat alignment—match the design.

Functional performance, including leak testing, opening pressure validation, and flow control behavior, especially important for valves used in food, medical, and dispensing applications.

Depending on the application, additional tests such as FDA compliance, material hardness (durometer) verification, or thermal resistance checks may be performed.

Working with a Professional Manufacturer of Silicone Valves

Silicone valves are critical components across industries such as medical devices, food and beverage packaging, personal care dispensers, and industrial fluid systems. Their role in controlling the flow of liquids or gases—often with precise, one-way operation—makes them indispensable in both high-performance and consumer-grade applications.

Given their functional importance, partnering with a professional silicone valve manufacturer is essential. A reliable manufacturer offers:

Expertise in material selection, ensuring the use of FDA- or LFGB-compliant silicone grades suited for your specific application.

Advanced mold design and tooling capabilities, resulting in consistent valve dimensions and repeatable performance.

Flexible production methods, including both compression and LSR injection molding, to accommodate different designs and order volumes.

Strict quality control protocols, with full traceability and testing that ensure each valve meets functional and regulatory standards.