silicone duckbill valve

- Home

- Products

- Silicone Valves

- Silicone duckbill valve

Understanding the Duckbill Valve: What Makes It Essential?

A silicone duckbill valve may seem like a small thing, but it plays a big role in fluid control. This clever one-way mechanism—often formed from high-grade silicone rubber—prevents reverse flow in medical devices, food packaging, baby products, and more. It’s flexible, precise, and dependable.

From pharmaceutical bottles to fuel systems, the silicone duckbill valve stands strong where other components falter. Its duckbill-shaped slit opens under pressure and seals tightly when backflow threatens. That’s where the magic lies.

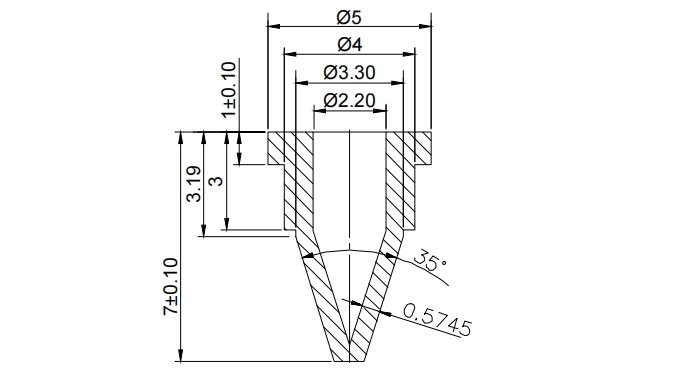

What size we have

silicone duckbill valve | Dispensing Control

Silicone Duckbill Valve | Dispensing Control

Applications

01

Medical

IV lines,respiratory masks,surgical fluid management,chemical lines

02

Automotive

Fuel vapor cooling systems,shampoo caps,condiment dispensers

03

Food & Beverage

Squeeze bottles, sauces, and beverage caps

abou Silicone Duckbill Valve What Our Clients Say

Why Partner With Us?

01

Expert tooling

We design custom valve molds in-house

02

Fast prototyping

7-day turnaround for test batches

03

Flexible MOQs

From startup runs to multi-million orders

Who Relies on Our Silicone Duckbill Valve Solutions?

We design every silicone duckbill check valve for long life and reliability. Our lab tests every batch for backpressure thresholds, opening angle consistency, and flow performance.

Global companies trust our silicone valves in the toughest environments. Some clients are household names. Others are startup innovators disrupting old industries. They all count on one thing—performance.

Material selection varies—platinum-cured or peroxide-cured silicone, translucent or pigmented, food-grade or industrial. No two projects need exactly the same valve. We build precisely what your application demands.

The Unmistakable Benefits of Our Dispensing Valves

Need specific features like heat resistance, FDA compliance, or compatibility with volatile fluids? We handle that. Our range includes:

Silicone check valves for high-purity systems

Silicone non return valves for bottle-top use

One way valve silicone inserts for medical-grade pumps

Silicone cross slit valve options for high-viscosity liquids

Low-profile silicone dispensing valve models for tight enclosures

We supply OEMs in:

Healthcare equipment manufacturing

Infant care and consumer goods

Nutraceutical packaging

Laboratory systems

Automotive tier suppliers

Beverage and sauce packaging lines

You ask, we answer

A: An umbrella valve seals around a central post. The duckbill seals along a horizontal slit. Duckbills typically have quicker response and cleaner reseal in low-pressure systems.

A: Maybe—but not always. The flow rate, cracking pressure, and valve orientation differ. Ask us—we’ll guide your choice.

A: Yes. Most silicone duckbill valves operate up to 200°C, depending on curing method and additive load. Tell us your limits.

A: Pressure chamber testing, UV dye tests, thermal cycling. No leak goes unnoticed.

A: Absolutely. From subtle tints for product lines to high-visibility indicators—we mold what you need.

Accessories & Others

Submit Your Sourcing Request

To get the fastest response, submit your inquiries using the form. If you encounter any issues with submission, you can also email us directly at info@xufucap.com.

All Valves in Stock | Fast Delivery

Get A Free Sample Now

Ready to ship within 3 days. Competitive price. Free samples available!

*Minimum order quantity of 10,000 units.