Flip Top Cap with Silicone Valve

- Home

- Products

- Flip top cap

- Flip Top Cap with Silicone Valve

What Makes So Effective?

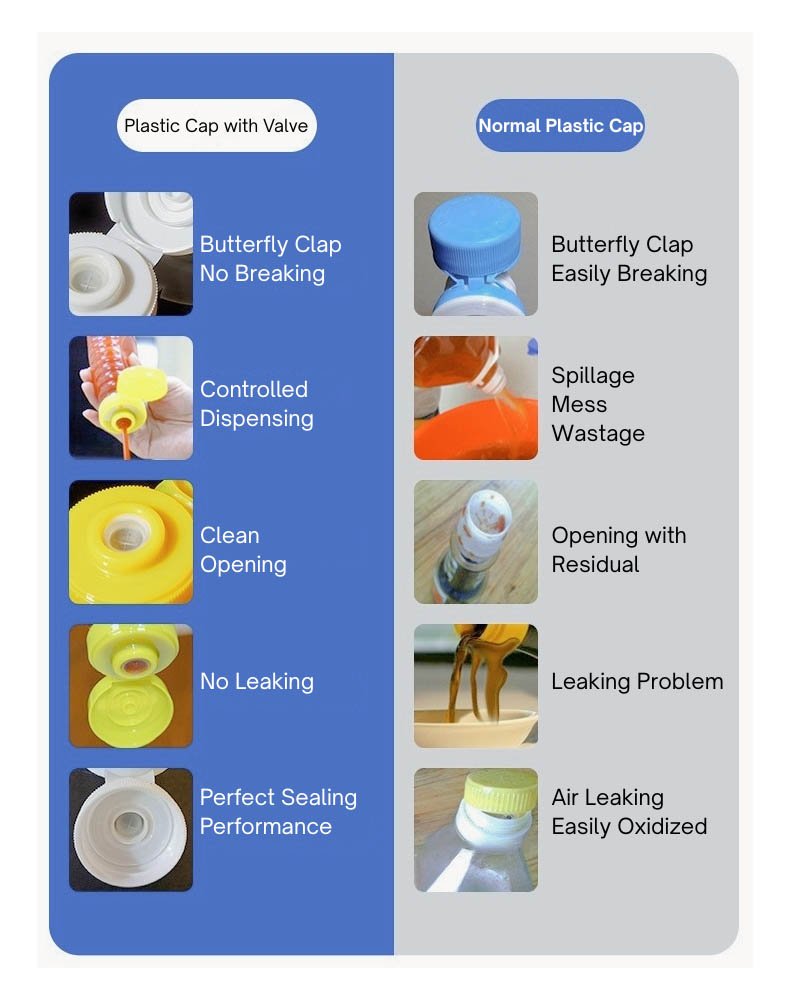

Flip top caps offer more than convenience. They:

Block contaminants from entering bottles

Reduce over-pouring or accidental spills

Snap shut firmly, even in transit

Fit most botellas de PET and HDPE containers

Pair well with both viscous and watery liquids

Simple squeeze. Perfect flow. Less mess.

*Minimum order quantity of 10,000 units.

Flip Top Cap with Silicone Valve: More Than a Lid

The Flip Top Cap with Silicone Valve changes how people handle liquid. From sauces to shampoos, it controls flow like a champ. You flip, squeeze, and get exactly what you need—no drips, no waste.

Whether fitted on 28 400 bottle caps or compact tampa flip top closures, these caps deliver both function and feel.

Product Details: Inside the Flip Top Cap with Silicone Valve

This isn’t a regular cap. It hides a cross-slit silicone valve inside. That valve opens under pressure, closes when released. No mess. No backflow.

Most come preassembled, combining PP resin bodies and food-safe silicone inserts. Threads match standard necks like 24/410, 28/400, or specialty forms.

What Is the Size and Why That Actually Matters

Size isn’t random. A 28 400 bottle cap suits large-mouthed bottles needing quick squeeze access. Smaller tampa flip top types handle lotions or oils.

Pick wrong and contents splatter or clog. Pick right and dispensing feels smooth, natural, effortless.

Who Uses It and Why It Works So Well

Food brands, beauty labels, even pharma pros count on it. Why? Because this cap works anywhere fluids demand control.

Personal care—serums, sunscreens. Condiments—ketchup, mayo. Cleaning agents—bleach, soap. All flow better with silicone-based regulation.

Features That Actually Solve Everyday Problems

Flip Action: Easy one-hand opening

Leak Barrier: Valve seals tightly between uses

Cross-Slit Tech: Prevents dribbles and reverse flow

Snug Threading: Fits industry necks without adapter rings

Reusable Design: Lasts through multiple refills

These features cut waste, reduce consumer hassle, and keep product costs low.

How Flip Top Cap with Silicone Valve Is Made

We start with virgin PP granules. Molded under high pressure, the cap takes form. Then comes the valve—precision-slit, food-grade silicone punched by rotary blade.

A final assembly fuses them into a single component. Every unit passes burst and leak tests.

Why Choose Us for Flip Top Cap with Silicone Valve Needs?

We’re not guessing—we mold, test, and refine every batch. Whether you want Flip Top Cap with cross-slit valves or wide-mouth 28 400 bottle caps, we’ve got stock molds or can tweak fast.

Need branding? No problem. Color matching, embossing, or matte finishes are available.

Shipping worldwide, we handle small MOQ requests or bulk OEM production equally fast.

Customers’ Common Questions—Answered in Plain Words

Q1: Does this cap work with thick liquids?

A1: Yes—cross-slit valves adapt to everything from water to viscous gel.

Q2: What thread sizes do you support?

A2: Standard 24/410, 28/400, plus custom necks on request.

Q3: Can I get samples?

A3: Absolutely. Just shoot over the address—we’ll ship next day.

Q4: Are these FDA compliant?

A4: Yes. Every silicone insert and resin body meets food-contact standards.

All Caps in Stock | Fast Delivery

Get A Free Sample Now

Ready to ship within 3 days. Competitive price. Free samples available!

*Minimum order quantity of 10,000 units.