Case Studies

- Home

- Case Studies

- Silicone Duckbill Valve for Fuel Tank Caps

Duckbill Combination Valve in Small Engine Fuel Tank Cap

Client Story: Australian Automotive Product Specialist

One of our clients, an automotive parts supplier in Australia, faced repeated issues with tank venting. Standard caps often leaked under pressure or failed to let in enough air, leading to vapor lock. Mechanics reported customer complaints about hard starts and stalling during hot weather.

By integrating our silicone duckbill check valve with an umbrella valve, they solved both problems. The duckbill allowed controlled one-way air entry while the umbrella vented excess vapor safely. Because our silicone valve retains shape after years of pressing, the cap stayed tight and reliable without costly replacements.

A silicone Duckbill Valve combined with an umbrella valve inside a small engine fuel tank cap solves a critical problem. Engines demand consistent fuel delivery, yet pressure changes in the tank can cause vapor buildup, leaks, or poor performance. This specialized valve design lets air enter the tank at low pressure as fuel is consumed while also venting vapor at higher pressure when the tank warms. The result is smooth operation, safe venting, and longer engine life.

What We Do: Reliable Silicone Valves for Automotive Applications

We design and produce:

Duckbill Valve systems for controlled airflow

Silicone one way valve inserts for venting safety

Cross-slit valves for custom fuel applications

Silicone check valve designs for durability under harsh conditions

Each valve meets strict automotive-grade requirements and is tested for fuel resistance, temperature endurance, and long-term resilience.

Why Choose Our Silicone Duckbill Valve Solutions?

Durability Under Compression – Always springs back, even after years of pressure.

Leak Protection – Prevents fuel seepage while allowing essential airflow.

Stable Engine Operation – Keeps fuel delivery consistent and avoids vapor lock.

Customizable Options – Wide range of dimensions, colors, and hardness levels.

Expert Engineering Support – From prototype through mass production.

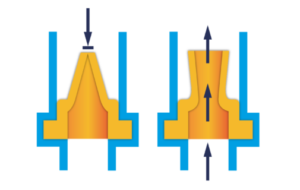

How the Umbrella/Duckbill Combination Valve Works in a Fuel Cap

Umbrella Valve Function: Opens when tank pressure rises, allowing vapor to escape.

Duckbill Valve Function: Opens only when negative pressure develops, letting air enter without fuel escaping.

Combination Effect: Together they stabilize pressure, extend engine life, and protect seals from wear.

Silicone Duckbill Valve vs Other Venting Designs

Silicone Duckbill Valve

Resists deformation

Ideal for one-way intake

Long-term elasticity

Umbrella Valve

Perfect for pressure venting

Lightweight and durable

Cross-Slit Valve

Opens under varied force

Customizable for niche needs

Silicone Check Valve

Maintains one-way flow

Works in both automotive and industrial settings

Customization Options for Automotive Partners

Shore hardness from soft to firm

Transparent, black, or color-matched silicone

Logo molding available for OEM identity

Valve sizes from 5mm to 40mm

Conclusion and Call to Action

For our Australian client, the umbrella/duckbill combination valve transformed fuel cap performance. No more vapor lock, no fuel leaks, and reliable airflow management across harsh weather conditions.

If you are developing or supplying small engine fuel systems, choose a silicone duckbill valve solution built for longevity and precision.

Reach out today for technical details, free samples, or design consultation.

All Valves in Stock | Fast Delivery

Get A Free Sample Now

Ready to ship within 3 days. Competitive price. Free samples available!

*Minimum order quantity of 10,000 units.