Tipos de válvulas de silicona

- Válvula unidireccional de silicona

- Válvula de hendidura transversal de silicona

- Junta de válvula de silicona

- Válvula de retención de tapón de botella

- Válvula de silicona para botellas de ketchup,etc...

Tamaños comunes

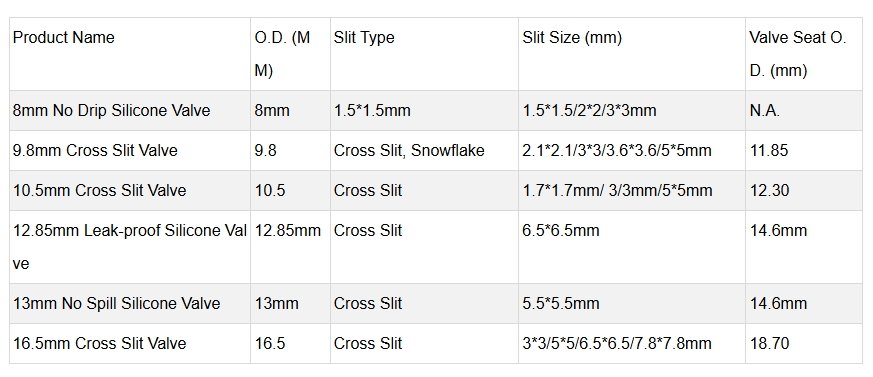

Las válvulas de silicona están disponibles en varios tamaños y pueden personalizarse en función de las necesidades específicas de cada aplicación. Los tamaños más comunes son:

Diámetro: 2mm - 50mm

Espesor: 0,3 mm - 5 mm

Tipos de apertura: Ranura en cruz, ranura en V, abertura circular, etc.

Tenemos T-10,T-13,T-16 tamaño en stock.

Aplicaciones

1. Industria alimentaria

Válvulas de retención de tapón de botella

Válvulas de silicona para botellas de ketchup

2. Medicina y farmacia

Control de fluidos en dispositivos médicos como equipos respiratorios y sistemas de inyección.

Válvulas de cierre en frascos de reactivos y envases farmacéuticos

3. Cuidado personal y cosmética

Dispensadores para productos de higiene y cuidado de la piel

Válvulas de silicona antirretorno en envases cosméticos.

4. Industria y automoción

Válvulas unidireccionales en gasoductos y conducciones de líquidos.

Componentes de control de fluidos en sistemas de combustible o refrigeración de automóviles.

5. Equipos de laboratorio y científicos

Válvulas de control de fluidos en instrumentos de precisión

Soluciones de sellado y dispensación para frascos de reactivos químicos.

Fabricación de válvulas de silicona: Métodos y resumen del proceso

Las válvulas de silicona son componentes esenciales en muchos sistemas de dosificación de fluidos, ya que ofrecen un control de precisión y una funcionalidad a prueba de fugas. Se fabrican por dos métodos principales: moldeo por compresión y moldeo por inyección de caucho de silicona líquida (LSR). El método elegido depende en gran medida de la estructura de la válvula y del volumen necesario.

Moldeo por compresión vs. Moldeo por inyección de LSR

Moldeo por compresión es ideal para lotes pequeños o diseños sencillos. Consiste en colocar silicona preformada en una cavidad de molde calentada y, a continuación, aplicar presión para darle forma.

Moldeo por inyección de LSRes el más adecuado para la producción de grandes volúmenes y geometrías complejas. Garantiza una calidad constante con tolerancias ajustadas, ideal para válvulas que requieren un rendimiento de precisión.

La importancia del diseño y la fabricación de moldes

En el corazón de la fabricación de válvulas de silicona se encuentra diseño y fabricación de moldes. Un molde bien diseñado garantiza la reproducción exacta de las especificaciones de la válvula, ya sea el tamaño, el diseño de la hendidura o la función de control del caudal.

Este paso comienza con una estrecha colaboración entre los ingenieros de producto y los diseñadores de moldes. Se utiliza software CAD avanzado para simular el comportamiento de la válvula en condiciones reales. Una vez finalizado, se fabrican herramientas de alta precisión mediante mecanizado CNC o EDM (mecanizado por descarga eléctrica), lo que garantiza que el molde cumple las estrictas normas del sector.

Un molde de alta calidad es fundamental: no sólo define el rendimiento de la válvula, sino que también determina la eficacia y longevidad del proceso de producción.

Inspección de calidad: Garantizar la precisión y el rendimiento

El paso final y más crítico en fabricación de válvulas de silicona es inspección de calidad. En esta fase, cada válvula se somete a una evaluación exhaustiva para garantizar que cumple las estrictas normas del sector y los requisitos específicos del cliente.

Los inspectores comprueban:

Defectos visuales como imperfecciones superficiales, alabeos o grietas.

Precisión dimensional utilizando herramientas de medición de precisión para verificar que las características críticas -como el grosor de la hendidura, el diámetro exterior y la alineación del asiento- coinciden con el diseño.

Rendimiento funcional, incluidas las pruebas de estanqueidad, la validación de la presión de apertura y el comportamiento del control de flujo, especialmente importantes para las válvulas utilizadas en aplicaciones alimentarias, médicas y de dispensación.

Dependiendo de la aplicación, pruebas adicionales como Cumplimiento de la FDA, verificación de la dureza del material (durómetro)o controles de resistencia térmica puede llevarse a cabo.

Trabajar con un fabricante profesional de válvulas de silicona

Las válvulas de silicona son componentes críticos en sectores como productos sanitarios, envases de alimentos y bebidas, dispensadores de productos de higiene personaly sistemas de fluidos industriales. Su función en el control del flujo de líquidos o gases -a menudo con un funcionamiento preciso y unidireccional- los hace indispensables tanto en aplicaciones de alto rendimiento como de consumo.

Dada su importancia funcional, asociación con un fabricante profesional de válvulas de silicona es esencial. Un fabricante fiable ofrece:

Experiencia en la selección de materialesgarantizando el uso de siliconas conformes a las normas FDA o LFGB adecuadas para su aplicación específica.

Capacidades avanzadas de diseño de moldes y utillajeEl resultado son unas dimensiones de válvula uniformes y un rendimiento repetible.

Métodos de producción flexiblesincluyendo el moldeo por inyección de LSR y compresión, para adaptarse a diferentes diseños y volúmenes de pedido.

Protocolos estrictos de control de calidad, con trazabilidad completa y pruebas que garantizan que cada válvula cumple las normas funcionales y reglamentarias.