De las bebidas a la belleza: Tapas Snap Top para todos los sectores

Tapas a presión se han convertido silenciosamente en un héroe del envasado moderno. Ya se trate de sorber una bebida deportiva, exprimir una loción o añadir una cucharada de salsa, estos tapones simplifican la vida. Su comodidad, versatilidad y sentido práctico explican por qué múltiples sectores -desde el de las bebidas al del cuidado personal- confían en ellos para su uso diario.

Industria de bebidas - Tapones a presión para refrescos

Las marcas de bebidas recurren a los tapones a presión para dispensar sin problemas y evitar derrames. Las bebidas deportivas, las aguas infusionadas y las bebidas energéticas suelen utilizar tapones de plástico flip top para ayudar a los consumidores a hidratarse sobre la marcha.

A diferencia de los tapones de rosca, los de presión se abren con un solo movimiento, lo que reduce las molestias para los usuarios activos. Combínalos con Tapones de botellas PET mantiene las bebidas frescas durante más tiempo.

Beneficios clave para las bebidas:

Manejo rápido con una sola mano para estilos de vida activos

Sello resistente para conservar la frescura

Funciona con botellas exprimibles con tapón abatible

Cuidado personal y belleza - Tapones a presión para mayor higiene y comodidad

En cosmética y cuidado de la piel, la presentación y la higiene tienen la misma importancia. Un tapón a presión ayuda a evitar derrames sucios y permite una dosificación controlada de cremas, geles y champús.

Los fabricantes de tapones abatibles de plástico también ofrecen acabados mates, brillantes o de colores que se adaptan a la estética de la marca.

Por qué las marcas de belleza eligen Snap Top Caps:

Mantiene las lociones libres de contaminación

Flujo de productos fluido y sin residuos

Opciones de tapón de boquilla personalizables para una aplicación específica

Referencias:

1. Cómo el cierre con válvula de silicona ayuda a mantener la calidad del producto

2. Diga adiós a los derrames: Cómo una válvula de hendidura transversal de silicona mejora la precisión y el control

3. Asegurar, Sellar, Proteger: El poder del envasado con cierre dispensador liberado

4. por qué el tapón abatible 28 410 es un cierre de dispensación superior para botellas

5. Tapón abatible con válvula de silicona para todo tipo de botellas

Farmacia y Salud - Tapones Snap Top para mayor seguridad

El envasado farmacéutico exige precisión, higiene y un diseño agradable para el paciente. A tapa abatible o tapa a presión sirve para medicamentos líquidos, jarabes o soluciones antisépticas sin contaminación cruzada.

Los proveedores de tapones abatibles de plástico suelen integrar precintos de seguridad para reforzar la seguridad y la confianza del consumidor.

Ventajas en el uso sanitario:

Dosificación precisa de gotas o chorros

Cierre seguro para evitar fugas accidentales

Compatible con productos de diferente viscosidad

Alimentos y condimentos - Tapas a presión para conservar el sabor

Ketchup, miel, aliño para ensaladas... muchos de los productos favoritos de la despensa confían en las tapas a presión para conservar su sabor. El sistema de cierre de la tapa limita la exposición al aire, lo que ralentiza el deterioro.

Un frasco exprimible con tapón abatible permite servir el producto de forma limpia y dosificada, reduciendo el desperdicio de producto.

Por qué las marcas de alimentación eligen Snap Top Caps:

Cierre hermético para mayor frescura

Fácil manejo con una sola mano en la cocina

Disponible en tamaños de tapón abatible 38/400 para botellas estándar

Productos para manualidades y bricolaje - Tapas a presión para mayor versatilidad

Los aficionados y los pequeños fabricantes también prefieren los tapones a presión para pegamento, pintura o materiales de artesanía. Un tapón de boquilla permite a los usuarios controlar la cantidad de material dispensado sin que se obstruya.

Los proveedores de tapones abatibles de plástico suelen suministrar lotes pequeños, lo que los hace idóneos para proyectos especializados.

Ventajas del bricolaje:

Formas de caño flexibles para materiales variados

Evita la suciedad accidental durante la aplicación

Se adapta a botellas de uso doméstico y comercial

Fabricación de tapas Snap Top: Cómo se fabrica

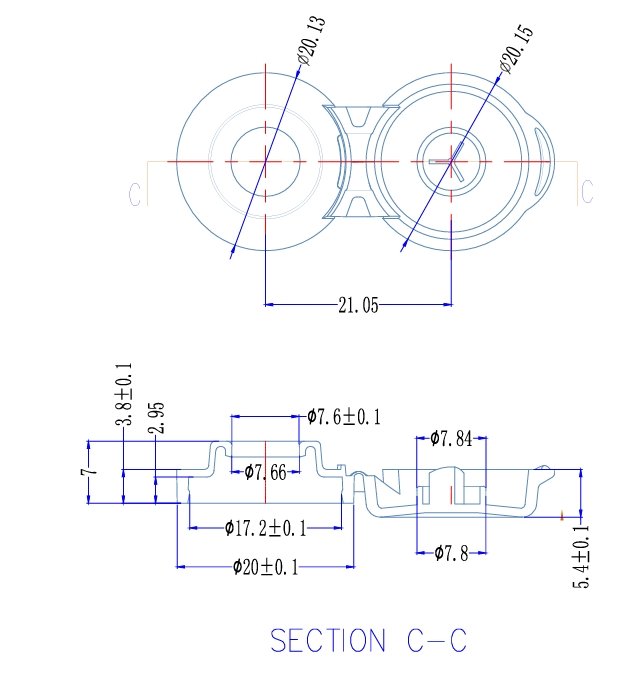

Fabricado mediante moldeo por inyección, cada tapa a presión se forma bajo temperaturas y presiones controladas con precisión.

Carga de material: Se añaden gránulos termoplásticos o de silicona.

Inyección: El plástico fundido rellena moldes de tapones a medida.

Enfriamiento y liberación: Los moldes se abren, los tapones caen sobre las cintas transportadoras.

Controles de calidad: Se comprueban la tensión, la resistencia de la bisagra y la precisión del sellado.

Grande fabricantes de tapones de botella pueden producir miles por hora. Los OEM más pequeños pueden ofrecer tiradas limitadas con moldes personalizados.

Respuestas a las preguntas más frecuentes de los clientes

P: ¿Puede funcionar un tapón a presión para productos de llenado en caliente?

R: Sí, algunos diseños de tapones de botellas de PET resisten condiciones moderadas de llenado en caliente.

P: ¿Funcionan los tapones a presión tanto para las fórmulas líquidas como para las espesas?

R: Por supuesto. La selección del diámetro correcto de la tapa de la boquilla garantiza un control adecuado del caudal.

P: ¿Son reciclables?

R: La mayoría de las tapas a presión fabricadas con PP o HDPE pueden reciclarse a través de los canales estándar.

Funciones que realmente resuelven los problemas de envasado

Los tapones a presión combinan un fácil acceso con la prevención de fugas. Ofrecen un flujo controlado, reducen el riesgo de contacto cruzado y ayudan a prolongar la vida útil del producto.

Su diseño ligero también reduce los gastos de envío en comparación con los cierres más pesados.

Ofrecemos una amplia gama de tamaños y colores personalizados

Desde pequeños tapones de boquilla para trabajos de precisión hasta grandes tapones abatibles 38/400 para salsas, nuestra selección lo cubre todo.

Los propietarios de marcas pueden elegir acabados transparentes, opacos o de colores a juego para reforzar la identidad de la marca.

Todas las tapas en stock | Entrega rápida

Obtenga ahora una muestra gratuita

Listo para enviar en 3 días. Precio competitivo. Muestras gratuitas disponibles.

*Cantidad mínima de pedido de 10.000 unidades.

Un comentario