valvola duckbill in silicone

- Casa

- Prodotti

- Valvole in silicone

- Valvola di chiusura in silicone

Capire la valvola Duckbill: Cosa la rende essenziale?

A valvola duckbill in silicone può sembrare una piccola cosa, ma svolge un ruolo importante nel controllo dei fluidi. Questo ingegnoso meccanismo unidirezionale, spesso realizzato in gomma siliconica di alta qualità, impedisce il flusso inverso nei dispositivi medici, negli imballaggi alimentari, nei prodotti per l'infanzia e altro ancora. È flessibile, preciso e affidabile.

Dai flaconi farmaceutici ai sistemi di alimentazione, il valvola duckbill in silicone è forte dove altri componenti vacillano. La sua fessura a forma di becco d'anatra si apre sotto pressione e si chiude ermeticamente quando il riflusso è minacciato. È qui che risiede la magia.

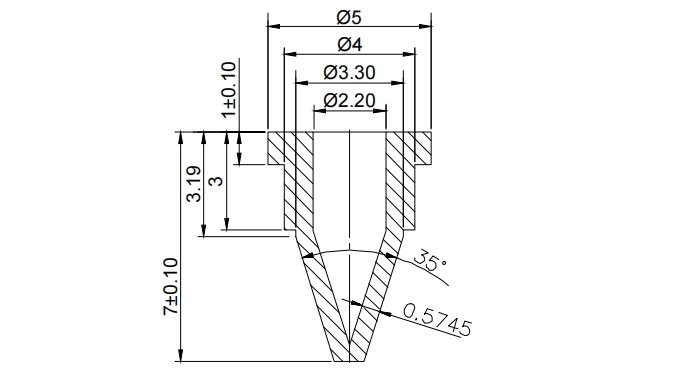

Che dimensioni abbiamo

Valvola a cerniera in silicone | Controllo dell'erogazione

Valvola a becco d'anatra in silicone - Controllo di erogazione

Applicazioni

01

Medico

Linee endovenose, maschere respiratorie, gestione dei fluidi chirurgici, linee chimiche

02

Automotive

Sistemi di raffreddamento dei vapori di carburante, tappi per shampoo, dispenser per condimenti

03

Cibo e bevande

Spremitura di bottiglie, salse e tappi per bevande

su Valvola antivibrante in silicone Cosa dicono i nostri clienti

Perché collaborare con noi?

01

Utensili esperti

Progettiamo internamente stampi per valvole personalizzati

02

Prototipazione rapida

Tempi di consegna di 7 giorni per i lotti di prova

03

MOQ flessibili

Dalla fase di avviamento agli ordini multimilionari

Chi si affida alle nostre soluzioni di valvole Duckbill in silicone?

Progettiamo ogni valvola di non ritorno in silicone per garantire lunga durata e affidabilità. Il nostro laboratorio testa ogni lotto per verificare le soglie di contropressione, la coerenza dell'angolo di apertura e le prestazioni di flusso.

Le aziende globali si affidano alle nostre valvole in silicone negli ambienti più difficili. Alcuni clienti sono nomi famosi. Altri sono startup innovative che stanno rivoluzionando vecchi settori. Tutti contano su una cosa: le prestazioni.

La scelta del materiale varia: silicone polimerizzato al platino o al perossido, traslucido o pigmentato, alimentare o industriale. Non esistono due progetti che necessitano esattamente della stessa valvola. Realizziamo esattamente ciò che richiede la vostra applicazione.

Gli inequivocabili vantaggi delle nostre valvole di dosaggio

Avete bisogno di caratteristiche specifiche come la resistenza al calore, la conformità alla FDA o la compatibilità con i fluidi volatili? Ce ne occupiamo noi. La nostra gamma comprende:

Valvole di ritegno in silicone per sistemi ad alta purezza

Valvole di non ritorno in silicone per uso in bottiglia

Valvola unidirezionale in silicone inserti per pompe per uso medico

Valvola a fessura trasversale in silicone opzioni per liquidi ad alta viscosità

Profilo basso valvola di erogazione in silicone modelli per ambienti ristretti

Forniamo OEM in:

Produzione di apparecchiature sanitarie

Prodotti per l'infanzia e beni di consumo

Confezionamento di prodotti nutraceutici

Sistemi di laboratorio

Fornitori di livello automobilistico

Linee di confezionamento per bevande e salse

Voi chiedete, noi rispondiamo

R: Una valvola a ombrello sigilla intorno a un palo centrale. L'otturatore sigilla lungo una fessura orizzontale. In genere, le valvole a becco d'anatra hanno una risposta più rapida e una richiusura più pulita nei sistemi a bassa pressione.

R: Forse, ma non sempre. La portata, la pressione di rottura e l'orientamento della valvola sono diversi. Chiedeteci di scegliere, vi guideremo nella scelta.

R: Sì. La maggior parte valvole duckbill in silicone operano fino a 200°C, a seconda del metodo di polimerizzazione e del carico di additivi. Comunicateci i vostri limiti.

R: Test in camera di pressione, test con coloranti UV, cicli termici. Nessuna perdita passa inosservata.

R: Assolutamente sì. Dalle tinte tenui per le linee di prodotto agli indicatori ad alta visibilità, noi produciamo ciò che vi serve.

Accessori e altro

Invia la tua richiesta di approvvigionamento

Per ottenere una risposta più rapida, inviate le vostre richieste utilizzando il modulo. In caso di problemi con l'invio, potete anche inviarci un'e-mail direttamente all'indirizzo info@xufucap.com.

Tutte le valvole in stock e consegna rapida

Richiedi subito un campione gratuito

Pronto per la spedizione entro 3 giorni. Prezzo competitivo. Campioni gratuiti disponibili!

*Quantità minima ordinabile di 10.000 unità.