フリップトップ・キャップの製造:総合ガイド

フリップトップ・キャップが重要な理由

フリップトップ・キャップ 日常生活をより快適に。バスルームのシャンプーボトルからキッチンのソース容器まで、これらのキャップは便利です。片手で操作でき、こぼれるのを防ぎ、製品の鮮度を保ちます。食品・飲料、化粧品、医薬品などの業界では、このキャップが頼りにされています。消費者は、信頼性と使いやすさでこれらのキャップを信頼しています。

フリップトップ・キャップができるまで

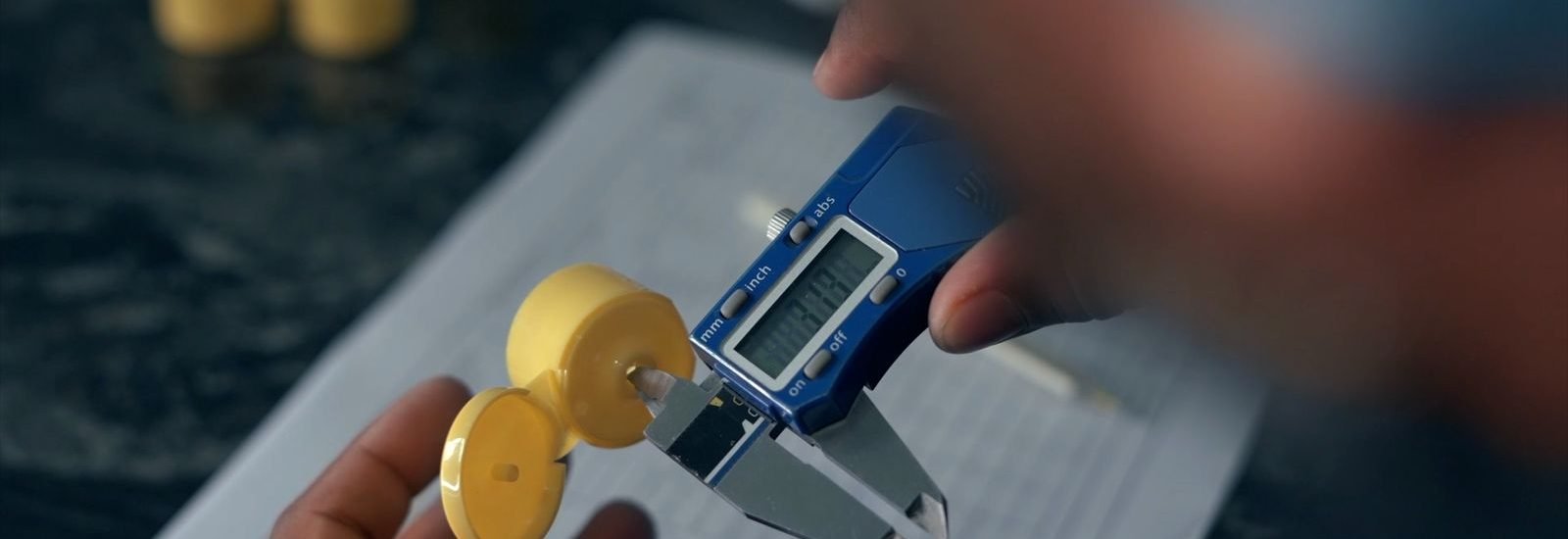

フリップトップ・キャップの製造 には精度が要求される。その工程は、プラスチック樹脂(多くはポリプロピレン)から始まる。この材料を溶かし、金型に注入し、キャップに成形する。冷却後、耐久性のあるヒンジを使って蓋が取り付けられる。品質チェックの後、キャップは包装の準備が整う。様々なサイズがある。 28/400 フリップトップ・キャップ, 28/410 フリップトップ・キャップ, 38 400 フリップトップ・キャップそして 38mm フリップトップ・キャップ. 各サイズは異なるタイプのボトルに適合し、ぴったりと密閉されます。

正しい選択 フリップトップ・キャップ・メーカー

最良のメーカーを選ぶには、慎重に考える必要がある。キャップはどれも同じではなく、小さな欠陥が漏れにつながることもあります。信頼できるサプライヤーは、一貫性、丈夫な素材、信頼できるシールを提供します。また ブラックフリップトップキャップ または ボート・フリップトップ・ガス・キャップ は特定の業界のニーズによって異なります。適切なパートナーは、規模に応じた品質を提供し、将来的な頭痛の種を防ぎます。

フリップトップ・キャップの重要性

フリップトップ・キャップは業界を問わず人気がある。その理由としては

- 使いやすく便利: フリップトップ・キャップは、使いやすく、時には片手でも使え、特にオイル、モイスチャライザー、ローション、シャンプーなどの製品については、密閉保護ができるように設計されているため、こぼれる可能性を減らすことができるため、消費者に好まれている。

- 清潔さと衛生: フリップトップ・キャップのフリップ機能により、製品は新鮮なまま保たれ、外部からの汚染はありません。

- 効率的で費用対効果が高い: フリップトップ・キャップは単価が安く、製造も簡単です。品質に妥協することなく、包装全体のコストを削減します。

何を見るべきか フリップトップ・キャップ

キャップはしっかりとフィットし、スムーズに開き、長持ちするものでなければならない。ボトルによっては ボトルフリップトップキャップ 圧力の変化に耐えるような機能を求める企業もあれば、簡単に絞れる機能を求める企業もある。これらの要素を理解することで、企業は賢い選択をすることができます。

結論

フリップトップ・キャップ 実用性と効率性を融合。製造は厳しい工程を経て行われ、耐久性と使いやすさを保証している。適切なメーカーを選ぶことが、すべての違いを生み出します。ソース、シャンプー、工業用液体のいずれにおいても、高品質のキャップは製品を安全かつ利用しやすい状態に保ちます。