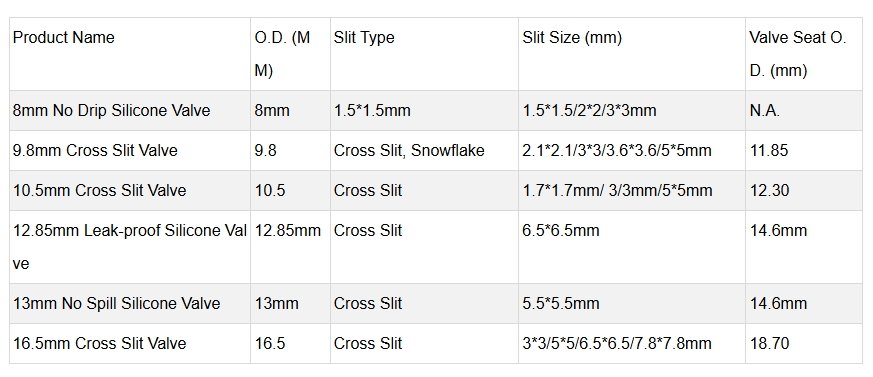

일반적인 크기

실리콘 밸브는 다양한 크기로 제공되며 특정 애플리케이션 요구 사항에 따라 맞춤 제작할 수 있습니다. 일반적인 크기는 다음과 같습니다:

직경 범위2mm - 50mm

두께: 0.3mm - 5mm

오프닝 유형: 크로스 슬릿, V자 슬릿, 원형 개구부 등

T-10, T-13, T-16 사이즈의 재고가 있습니다.

애플리케이션

1. 식음료 산업

병뚜껑 체크 밸브

케첩 병 실리콘 밸브

2. 의료 및 제약

호흡기 장비 및 주사 시스템과 같은 의료 기기의 유체 제어.

시약 병 및 제약 용기의 밀봉 밸브

3. 퍼스널 케어 및 화장품

스킨케어 및 위생 제품용 디스펜서

화장품 포장의 역류 방지 실리콘 밸브.

4. 산업 및 자동차

가스 및 액체 파이프라인의 단방향 밸브.

자동차 연료 또는 냉각 시스템의 유체 제어 부품.

5. 실험실 및 과학 장비

정밀 계측기의 유체 제어 밸브

화학 시약 병을 위한 밀봉 및 디스펜싱 솔루션.

실리콘 밸브 제조: 방법 및 공정 개요

실리콘 밸브는 많은 유체 디스펜싱 시스템의 필수 구성 요소로, 정밀 제어 및 누출 방지 기능을 제공합니다. 실리콘 밸브의 제조에는 두 가지 주요 방법이 사용됩니다: 압축 성형 그리고 액상 실리콘 고무(LSR) 사출 성형. 선택한 방법은 밸브의 구조와 필요한 부피에 따라 크게 달라집니다.

압축 성형과 LSR 사출 성형 비교

압축 성형 은 소량 배치 또는 간단한 디자인에 이상적입니다. 사전 성형된 실리콘을 가열된 몰드 캐비티에 넣은 다음 압력을 가하여 모양을 만드는 방식입니다.

LSR 사출 성형는 대량 생산 및 복잡한 형상에 가장 적합합니다. 엄격한 공차로 일관된 품질을 보장하며 정밀 성능이 요구되는 밸브에 이상적입니다.

금형 설계 및 제작의 중요성

실리콘 밸브 제조의 핵심은 다음과 같습니다. 금형 설계 및 금형 제작. 잘 설계된 금형은 크기, 슬릿 디자인 또는 유량 제어 기능 등 밸브의 사양을 정확하게 복제할 수 있습니다.

이 단계는 제품 엔지니어와 금형 설계자 간의 긴밀한 협업으로 시작됩니다. 고급 CAD 소프트웨어를 사용하여 실제 조건에서 밸브의 동작을 시뮬레이션합니다. 최종 설계가 완료되면 CNC 가공 또는 EDM(방전 가공)을 사용하여 고정밀 툴링을 제작하여 금형이 엄격한 산업 표준을 충족하도록 합니다.

고품질 금형은 밸브의 성능을 정의할 뿐만 아니라 생산 공정의 효율성과 수명을 결정하기 때문에 매우 중요합니다.

품질 검사: 정밀도 및 성능 보장

의 마지막이자 가장 중요한 단계 실리콘 밸브 제조 는 품질 검사. 이 단계에서 각 밸브는 엄격한 산업 표준 및 고객별 요구 사항을 충족하는지 확인하기 위해 철저한 평가를 거칩니다.

검사자는 다음을 확인합니다:

시각적 결함 표면 결점, 뒤틀림 또는 깜박임과 같은 문제입니다.

치수 정확도 정밀 측정 도구를 사용하여 슬릿 두께, 외경, 시트 정렬과 같은 중요한 특징이 설계와 일치하는지 확인합니다.

기능적 성능누출 테스트, 개방 압력 검증 및 유량 제어 동작을 포함하여 식품, 의료 및 디스펜싱 애플리케이션에 사용되는 밸브에 특히 중요합니다.

애플리케이션에 따라 다음과 같은 추가 테스트가 필요합니다. FDA 규정 준수, 재료 경도(경도계) 검증또는 내열성 검사 를 수행할 수 있습니다.

실리콘 밸브 전문 제조업체와 협력

실리콘 밸브는 다음과 같은 산업 전반에 걸쳐 중요한 구성 요소입니다. 의료 기기, 식음료 포장, 퍼스널 케어 디스펜서및 산업용 유체 시스템. 액체 또는 가스의 흐름을 제어하는 역할(종종 정밀한 단방향 작동)을 수행하므로 고성능 및 소비자 등급 애플리케이션 모두에서 없어서는 안 될 필수 요소입니다.

기능적 중요성을 고려할 때 전문 실리콘 밸브 제조업체와의 파트너십 는 필수입니다. 신뢰할 수 있는 제조업체가 제공합니다:

소재 선택에 대한 전문성를 통해 특정 용도에 적합한 FDA 또는 LFGB 준수 실리콘 등급을 사용할 수 있습니다.

고급 금형 설계 및 툴링 기능를 사용하여 일관된 밸브 치수와 반복 가능한 성능을 제공합니다.

유연한 제작 방법압축 성형과 LSR 사출 성형을 모두 포함하여 다양한 디자인과 주문량을 수용할 수 있습니다.

엄격한 품질 관리 프로토콜각 밸브가 기능 및 규제 표준을 충족하는지 확인하기 위한 완전한 추적성 및 테스트를 제공합니다.