Silikoniniai vožtuvai

- Pagrindinis

- Produktai

- Silikoniniai vožtuvai

Silikoninių vožtuvų tipai

- Silikoninis vienpusis vožtuvas

- Silikoninis kryžminis plyšinis vožtuvas

- Silikoninis vožtuvo sandariklis

- Butelio dangtelio kontrolinis vožtuvas

- Kečupo butelių silikoninis vožtuvas ir kt.

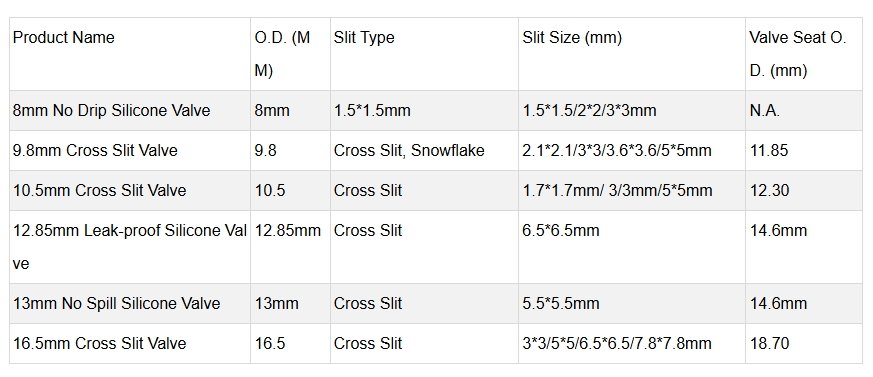

Įprasti dydžiai

Silikoniniai vožtuvai būna įvairių dydžių ir gali būti pritaikyti pagal konkrečius naudojimo poreikius. Dažniausiai pasitaikantys dydžiai yra šie:

Skersmens diapazonas: 2 mm - 50 mm

Storis: 0,3 mm - 5 mm

Atidarymo tipai: Kryžminis plyšys, V formos plyšys, apskrita anga ir t. t.

Turime T-10, T-13, T-16 dydžio atsargų.

Paraiškos

1. Maisto ir gėrimų pramonė

Butelių dangtelių atbuliniai vožtuvai

Kečupo butelių silikoniniai vožtuvai

2. Medicina ir farmacija

skysčių kontrolė medicinos prietaisuose, pavyzdžiui, kvėpavimo įrangoje ir įpurškimo sistemose.

Reagentų buteliukų ir vaistų talpyklų sandarinimo vožtuvai

3. Asmens higiena ir kosmetika

Odos priežiūros ir higienos priemonių dozatoriai

Silikoniniai vožtuvai, apsaugantys nuo grįžtamojo srauto, kosmetikos pakuotėse.

4. Pramonės ir automobilių pramonė

Vienkrypčiai dujų ir skysčių vamzdynų vožtuvai.

Automobilių degalų arba aušinimo sistemų skysčių valdymo komponentai.

5. Laboratorinė ir mokslinė įranga

Skysčių valdymo vožtuvai tiksliuosiuose prietaisuose

Cheminių reagentų buteliukų sandarinimo ir dozavimo sprendimai.

Silikoninių vožtuvų gamyba: Metodų ir procesų apžvalga

Silikoniniai vožtuvai yra esminiai daugelio skysčių dozavimo sistemų komponentai, užtikrinantys tikslų valdymą ir sandarumą. Jie gaminami dviem pagrindiniais būdais: suspaudimo liejimas ir skysto silikoninio kaučiuko (LSR) liejimas. Pasirinktas metodas labai priklauso nuo vožtuvo konstrukcijos ir reikiamo tūrio.

Presinis liejimas ir LSR liejimas įpurškimo būdu

Suspaudimo liejimas idealiai tinka mažesnėms partijoms arba paprastiems projektams. Į šildomą formos ertmę įdedamas iš anksto paruoštas silikonas, tada spaudžiant formuojama forma.

LSR įpurškiamasis liejimasKita vertus, jis geriausiai tinka didelės apimties gamybai ir sudėtingoms geometrijoms. Ji užtikrina pastovią kokybę su mažais nuokrypiais, idealiai tinka vožtuvams, kuriems reikia tikslaus veikimo.

Formos projektavimo ir gamybos svarba

Silikoninių vožtuvų gamybos pagrindas yra pelėsių projektavimas ir pelėsių gamyba. Gerai suprojektuota liejimo forma užtikrina tikslų vožtuvo specifikacijų atkartojimą - ar tai būtų dydis, ar plyšio konstrukcija, ar srauto valdymo funkcija.

Šis etapas prasideda nuo glaudaus gaminių inžinierių ir liejimo formų projektuotojų bendradarbiavimo. Pažangi CAD programinė įranga naudojama vožtuvo elgsenai realiomis sąlygomis modeliuoti. Baigus darbą, CNC apdirbimo arba EDM (elektros išlydžio apdirbimo) būdu gaminami didelio tikslumo įrankiai, užtikrinantys, kad forma atitiktų griežtus pramonės standartus.

Aukštos kokybės liejimo forma yra labai svarbi - nuo jos priklauso ne tik vožtuvo veikimas, bet ir gamybos proceso efektyvumas bei ilgaamžiškumas.

Kokybės tikrinimas: Tikslumo ir našumo užtikrinimas

Paskutinis ir svarbiausias žingsnis Silikono vožtuvų gamyba yra . kokybės tikrinimas. Šiame etape kiekvienas vožtuvas kruopščiai įvertinamas, kad būtų užtikrinta, jog jis atitinka griežtus pramonės standartus ir konkretaus kliento reikalavimus.

Inspektoriai tikrina, ar:

Vizualiniai defektai pavyzdžiui, paviršiaus defektai, deformacijos ar išsikraipymai.

Matmenų tikslumas naudojant tiksliuosius matavimo įrankius patikrinti, ar svarbiausios savybės, pavyzdžiui, plyšio storis, išorinis skersmuo ir sėdynės išsidėstymas, atitinka projektą.

Funkcinis veikimasįskaitant sandarumo bandymus, atidarymo slėgio patvirtinimą ir srauto valdymo charakteristikas, ypač svarbias vožtuvams, naudojamiems maisto, medicinos ir dozavimo srityse.

Priklausomai nuo taikomosios programos, gali būti atliekami papildomi testai, pvz. FDA atitiktis, medžiagos kietumo (durometro) patikrinimas, arba šiluminės varžos patikrinimai gali būti atliekamas.

Darbas su profesionaliu silikoninių vožtuvų gamintoju

Silikoniniai vožtuvai yra labai svarbūs komponentai įvairiose pramonės šakose, pvz. medicinos prietaisai, maisto ir gėrimų pakuotės, asmens higienos dozatoriai., ir pramoninės skysčių sistemos. Dėl jų vaidmens kontroliuojant skysčių ar dujų srautą - dažnai tiksliai ir vienpusiškai - jie yra nepakeičiami tiek didelio našumo, tiek plataus vartojimo prietaisuose.

Atsižvelgiant į jų funkcinę svarbą, bendradarbiavimas su profesionaliu silikoninių vožtuvų gamintoju yra labai svarbus. Patikimas gamintojas siūlo:

Medžiagų pasirinkimo patirtisužtikrinant, kad būtų naudojamos FDA arba LFGB reikalavimus atitinkančios silikono rūšys, tinkamos konkrečiai jūsų paskirčiai.

Pažangios formos projektavimo ir įrankių kūrimo galimybės, todėl vožtuvo matmenys yra vienodi ir veikimas pasikartoja.

Lankstūs gamybos metodai, įskaitant tiek suspaudimo, tiek LSR įpurškimo liejimą, kad būtų galima pritaikyti skirtingus dizainus ir užsakymų kiekius.

Griežti kokybės kontrolės protokolaisu visišku atsekamumu ir bandymais, užtikrinančiais, kad kiekvienas vožtuvas atitiktų funkcinius ir reguliavimo standartus.