38 400 vippelokk

- Hjem

- Produkter

- Flip top cap

- 38 400 vippelokk

38 400 flip top-lokket ser kanskje ut som en liten detalj, men det er et av de mest praktiske lukkesystemene du noensinne vil støte på. Enten du jobber med kosmetikk, matemballasje, personlig pleie eller industrielle applikasjoner - denne korken holder alt sammen. Det er ikke tilfeldig at den er så populær blant plastkapsler. Den kommer av presisjon, formål og en gjennomtenkt design.

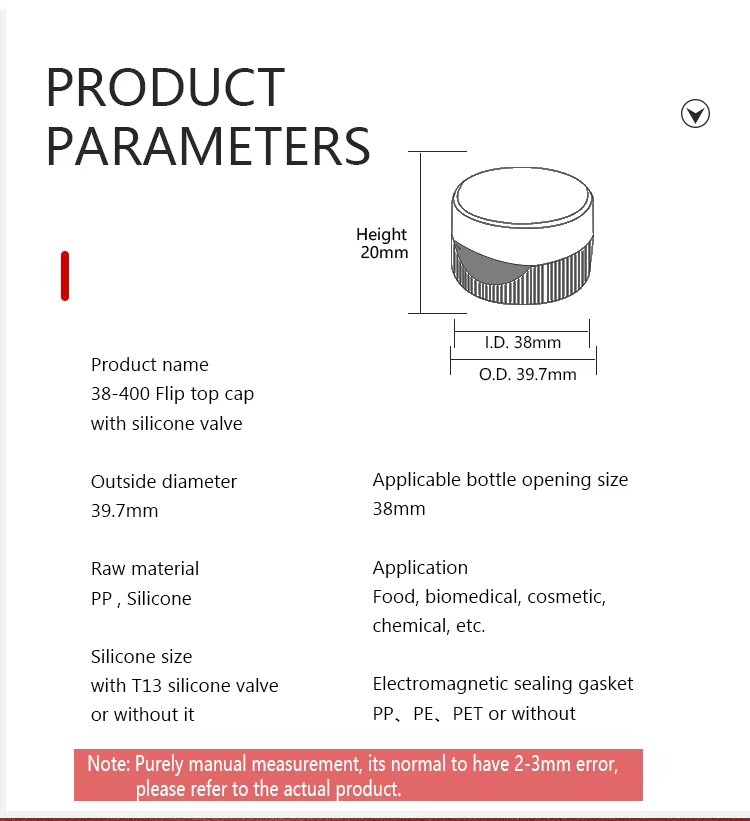

Produktdetaljer:

A 38 400 vippelokk er en lukkemekanisme med en diameter på 38 mm og gjengestigning som er kompatibel med flasker i 400-serien. Det betyr at den sitter tett, uten lekkasjer eller problemer. Korken åpnes enkelt - ideelt for enhåndsdispensering. Denne størrelsen brukes ofte i bransjer som krever pålitelig flytkontroll og brukervennlighet.

Sammenlignet med skrukorker eller snapkorker gir 38-400 flip top raskere tilgang og enklere gjenforsegling. Derfor er den en favoritt blant merker som tilbyr tyktflytende produkter som ketchup, sjampo eller til og med sportsgeler.

Hva er størrelsen, og hvorfor er den viktig?

"38" refererer til den ytre diameteren i millimeter. "400" angir gjengestil og -dybde. Sammen, 38 mm flaskekapsler av plast med 400 gjenger sikrer kompatibilitet med standard halsflasker, spesielt PET- eller HDPE-beholdere.

Hvorfor er dette viktig? Fordi pakkelinjene må fungere problemfritt. Bruk av 38 400 flaskekorker betyr færre produksjonsproblemer, og det blir mindre risikabelt å bytte leverandør.

Hvem bruker 38-400 flaskekapsler?

Disse plasthettene med vippbar topp brukes i mange bransjer:

Mat og drikke: Saus, sirup, olje, honning

Personlig pleie: Sjampo, balsam, bodylotion

Farmasøytisk: Sirupflasker, reseptfrie kremdispensere

Industriell: Rengjøringsmidler, kjemikaliedosering

Hvorfor denne lukkingen fungerer så bra

Det er mange grunner til at akkurat denne skrukorken er så god. For det første skruelokk med vippelokk er intuitive. Du trenger ingen instruksjoner for å åpne dem. For det andre er de trygge - barn kan ikke enkelt fjerne dem uten hjelp fra voksne, selv om de ikke er klassifisert som barnesikre.

Legg til valgfritt flip top cap mold Med funksjoner som manipuleringssikre bånd eller induksjonsforsegling, har du en emballasjeløsning som skaper tillit.

Nøkkelegenskaper ved 38 400 Flip Top plasthetter

Noen av de fremtredende funksjonene i 38 mm flaskekapsler:

Hengslet lokk: Flippes opp med én hånd

Sikker forsegling: Forhindrer lekkasje under transport

Matvaregodkjent materiale: Ofte laget av PP eller HDPE

Kan tilpasses: Pregede logoer, fargematching, ventilinnsatser

Tett passform: Konstruert for standard 38-400 halsgjenger

Hvor kan du bruke vippelokk i plast?

Du vil finne plasthetter med vippelokk på:

Tannkremtuber (ja, vippelokk for tannkremtuber er en hel nisje)

Flasker med flytende såpe

Proteindrikker

Kosttilskudd for trening

Håndverkslim

Hvordan lage en Flip Top Cap: Et raskt innblikk i prosessen

Produksjon av en 38 400 vippelokk starter med en nøye utformet støpeform - ofte av stål eller aluminium. Lokkets struktur trenger en design av støpeform med vippelokk som støtter hengselmekanismen uten å gå i stykker etter tusenvis av bruksområder.

Her er den typiske prosessen:

Utforming av støpeformen: Ingeniører utvikler en form for vippelokk ved hjelp av CAD-programvare. Ventilspor eller logoer kan inkluderes her.

Sprøytestøping: Polypropylen varmes opp og sprøytes inn i formen.

Kjøling og utstøting: Hetten kjøles ned og skytes ut med presisjon.

Montering: Hvis det er behov for silikonventiler eller -foringer, legges de til etter støpingen.

QC-sjekk: Lokkene gjennomgår lekkasje- og passformtesting før pakking.

Samarbeid med en ekspert produsent av vippelokk betyr færre feil, raskere produksjonssykluser og bedre konsistens på tvers av partier.

Hvorfor velge oss som din produsent av vippelokk?

Her er hva som skiller oss ut som en av de mest pålitelige leverandører av flip top cap:

Egen utvikling av støpeformer: Vi skaper hver eneste flip top cap mold selv, noe som reduserer ledetidene.

Tilpassede ventilalternativer: Trenger du en vippelokk med silikonventil? Ikke noe problem.

Fleksibilitet i materialet: Vi tilbyr både jomfruelig og resirkulert PP, avhengig av kundens mål.

Global etterlevelse: FDA-godkjente materialer, REACH-testet og matsikkert.

Bulkoppfyllelse: Fra MOQ til fulle containere, vi kan håndtere det.

Enten du skal starte en ny produktserie eller bytte ut utdaterte lukninger, kan teamet vårt levere skalerbare emballasjeløsninger uten forsinkelse.

Svar på vanlige spørsmål fra kunder

Spørsmål: Kan disse hettene resirkuleres?

Ja. De fleste 38 mm flaskekapsler av plast er polypropylenbaserte og resirkulerbare der det finnes anlegg for dette.

Spørsmål: Passer denne hetten til alle 38-400-flasker?

Hvis halsfinishen stemmer overens, ja. Men det er alltid lurt å teste - flasketoleransene varierer litt fra produsent til produsent.

Spørsmål: Hva er forskjellen mellom 38 400 og 38 410?

Gjengedybde og -avstand. Hvis flasken din er merket 38-400, er det bare den typen som passer.

Hvorfor 38 400 Flip Top Cap fortjener din oppmerksomhet

Når presisjon er viktig og bekvemmelighet betyr enda mer, er 38 400 vippelokk leverer begge deler. Med design som kan tilpasses, fleksibilitet i formene og støtte for høyhastighetsfyllelinjer, er det ingen overraskelse at denne lukkingen er den beste i emballasjeverdenen for mat, personlig pleie og mye mer.

Ikke slå deg til ro med det som er billig eller "helt greit". Samarbeid med erfarne produsenter av vippelokk som forstår formtoleranse, linertilpasning og produksjonskonsistens. Flaskekorken er ikke bare plast - den er produktets ansikt utad.