odkręcana nasadka

- Strona główna

- Produkty

- Odchylana górna nasadka

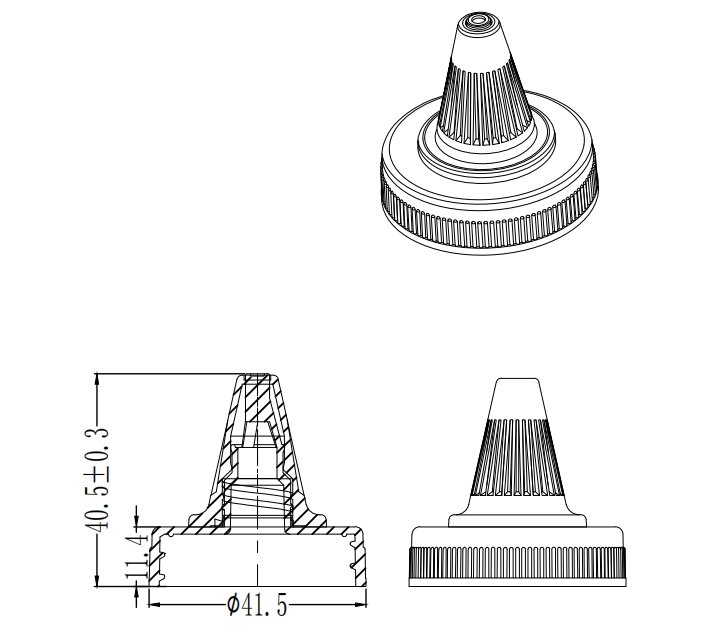

- Przekręcana nasadka

Wszystko, co musisz wiedzieć o Twist Open Cap

Szukasz nie przeciekającego, łatwego w użyciu, przekręcanego zamknięcia? The odkręcana nasadka może być świętym Graalem w dziedzinie opakowań. Niezależnie od tego, czy jesteś królem przypraw, marką środków higieny osobistej, czy rozlewnią napojów, rozwiązania z zakręcanym wieczkiem oferują przede wszystkim jedną kluczową cechę: kontrolę. W tym artykule zagłębiamy się we wszystko, co najważniejsze - obejmując specyfikacje produktów, rozmiary, produkcję, przypadki użycia i dlaczego marki na całym świecie wciąż wybierają zakręcane nasadki dozujące.

Czym dokładnie jest czapka Twist Open?

A odkręcana nasadka-czasami nazywany zakręcana nasadka lub odkręcana zakrętka butelki-to obrotowy system zamykania zaprojektowany z myślą o wygodnym dozowaniu. Chwytasz, przekręcasz, nalewasz lub wyciskasz. Zakrętki te mają zazwyczaj gwintowaną konstrukcję, która po obróceniu otwiera centralny otwór.

W przeciwieństwie do zakrętek typu flip cap lub push-pull, ten jest czysty. Pokrywka nie otwiera się w niezręczny sposób, a na jej powierzchni nie gromadzą się żadne pozostałości.

Są szczególnie popularne w liniach produktów o wysokiej lepkości: miód, szampon, żele sportowe, sosy. To nie przypadek.

Dlaczego rozmiar czapki ma znaczenie (i na jakich rozmiarach powinno ci zależeć)?

Rozmiar to nie tylko dopasowanie - wpływa on na ciśnienie, natężenie przepływu i kompatybilność z półkami. Standardowe rozmiary wahają się od 24 mm do 38 mm, a prawidłowy rozmiar zakrętki twist top zależy od:

Wykończenie szyi butelki (np. 28-410)

Lepkość produktu

Siła i zręczność użytkownika

Na przykład model 24-410 może być odpowiedni do cieńszych płynów. Ale jeśli pakujesz coś gęstszego, jak sos BBQ lub balsam? Będziesz potrzebował szerszego otworu. Niewłaściwe dopasowanie oznacza wyciek, słaby przepływ lub - co gorsza - skargi klientów.

Kto używa czapek Twist Open (i dlaczego wygrywają)?

Od globalne łańcuchy żywnościowe do Niezależni producenci szamponówWszyscy wskakują na pokład otwartego pociągu twist.

Firmy produkujące przyprawy: Pożegnaj się z niechlujnym rozpryskiwaniem ketchupu. Przekręcana zakrętka butelki zapewnia konsumentom precyzyjną kontrolę.

Marki produktów higieny osobistej: Użytkownicy nie potrzebują dwóch rąk ani blatu - wystarczy przekręcić, dozować i gotowe.

Produkty outdoorowe: W przypadku butelek podróżnych, żeli i filtrów przeciwsłonecznych nic nie przebije funkcjonalności jednej ręki i bezpieczeństwa uszczelnienia.

Dlaczego? Ponieważ te nasadki rozwiązują rzeczywiste problemy użytkowników - rozlania, przelania, zablokowane zamknięcia.

Funkcje, które faktycznie rozwiązują rzeczywiste problemy związane z opakowaniami

Porzućmy puch i porozmawiajmy o rzeczywistej użyteczności. Dobry odkręcana nasadka dozująca obsługuje więcej niż estetykę.

✔ Odporność na wycieki: Większość zakręcanych pokryw posiada wewnętrzne uszczelki, które zapobiegają wyciekaniu produktu.

✔ Kontrolowane dozowanie: Otwiera się tylko po przekręceniu - więc małe dzieci i TSA nie sieją spustoszenia.

✔ Czyste linie: Zakręcane pokrywki eliminują potrzebę stosowania dodatkowych pokrywek lub klapek.

✔ Wybór materiałów: Dostępne w wersjach z HDPE, PP, a nawet mieszanek PET zapewniających bezpieczeństwo żywności lub kompatybilność chemiczną.

✔ Kodowanie kolorami: Idealny do wyróżnienia produktu na półce lub w zestawach.

Jak powstaje zakrętka Twist Open Cap? (Spojrzenie zza kulis)

Produkcja a odkręcana nasadka obejmuje precyzyjne formowanie wtryskowe tworzyw sztucznych. Oto krótki podział:

Projektowanie i tworzenie form

Oprogramowanie CAD definiuje gwinty śrub, żebra blokujące i punkty uszczelnienia. Metalowa forma jest obrabiana CNC w celu odzwierciedlenia tego projektu.Formowanie wtryskowe

Stopione tworzywo sztuczne (PP, HDPE lub inna żywica) jest wtryskiwane do formy z dużą prędkością i pod wysokim ciśnieniem.Chłodzenie i wyrzut

Po zestaleniu nasadka jest zwalniana. Automatyzacja często przejmuje kontrolę.Montaż (jeśli wieloczęściowy)

Niektóre skręcane, otwarte nasadki składają się z zewnętrznej powłoki i obracającego się rdzenia wewnętrznego.Kontrole jakości

Nasadki są testowane pod kątem momentu obrotowego, szczelności i tolerancji wymiarowych.

Wielkie nazwiska producenci zakrętek używają sprzętu o wysokiej wydajności, aby nadążyć za popytem i spełnić globalne standardy zgodności.

Dlaczego warto wybrać właśnie nas?

Chcesz niezawodności, a nie zgadywania. To właśnie tutaj produkcja zakrętek usługa wyróżnia się.

Dziesięciolecia doświadczenia w formowaniu

Konfigurowalne projekty dla każdej linii produktów

Niskie MOQ i szybki czas realizacji

Żywice klasy FDA do zastosowań spożywczych i higieny osobistej

Testy szczelności przed wysyłką

Dostarczyliśmy miliony Zakrętki dozujące typu twist open na całym świecie - każdy z nich został stworzony, aby pomóc Twojemu produktowi wyróżnić się i działać lepiej.

Najczęstsze pytania klientów - odpowiedzi

Czy zakrętki mogą być poddawane recyklingowi?

Tak - większość z nich jest wykonana z nadającego się do recyklingu PP lub HDPE. Wystarczy sprawdzić lokalne przepisy dotyczące recyklingu.

Czy zakrętki są zabezpieczone przed dziećmi?

Niektóre wersje mogą być. Zapytaj swojego dostawcę o modele z certyfikatem CR, jeśli sprzedajesz leki lub niebezpieczne płyny.

Czy mogę ich używać do produktów napełnianych na gorąco?

Zależy to od żywicy i konstrukcji formy. Zalecamy przetestowanie partii próbnej z dokładną temperaturą wypełnienia.

Jak mogę spersonalizować zakrętkę do butelki?

Wybieraj spośród wielu kolorów, średnic, materiałów, opcji wytłaczania, a nawet opasek zabezpieczających przed manipulacją.

Odpowiednia nasadka może zepsuć produkt

Bez przesady - źle dobrana nakładka niszczy atrakcyjność półki, frustruje użytkowników i powoduje zwroty. Mądrze dobrana odkręcana nasadka? To podnosi rangę marki.

Nie tylko zamykasz butelkę - zamykasz zaufanie klienta. Wybierz nakrętkę, która działa, wygląda dobrze i nigdy nie przecieka. Wybierz taki, który ma cel.

Wszystkie czapki w magazynie | Szybka dostawa

Pobierz bezpłatną próbkę już teraz

Gotowy do wysyłki w ciągu 3 dni. Konkurencyjna cena. Dostępne bezpłatne próbki!

*Minimalna ilość zamówienia 10 000 sztuk.